What is IML?

Understanding In- Mould Labelling

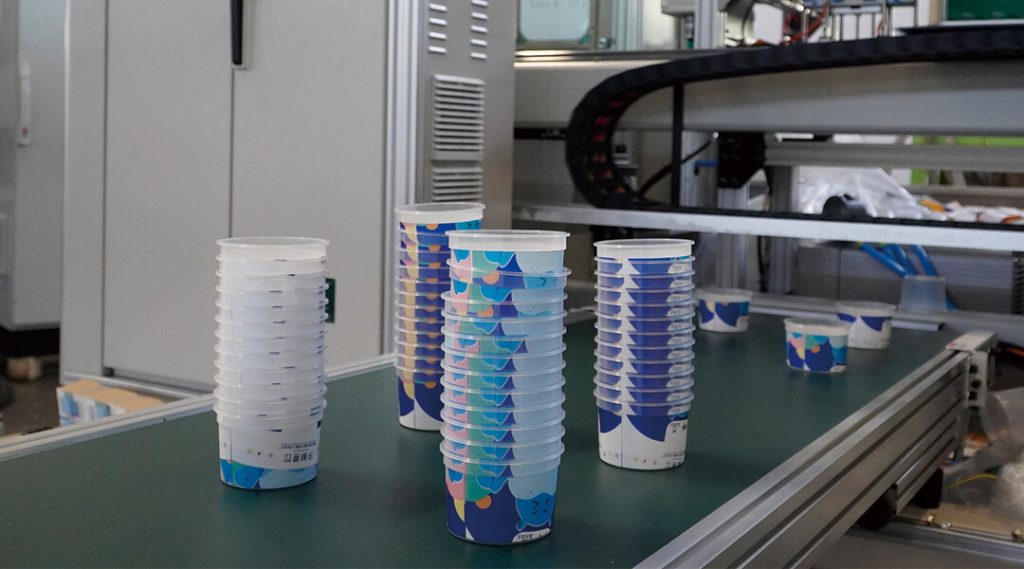

In mould labelling (IML) is an innovative technique where a pre-printed label is placed inside the mould before the plastic container takes shape. As the plastic resin or pellets are heated and injected into the mould, the label and container fuse into one seamless product.

Common Materials Used in In Mould Labelling

The two most common plastics used for injection moulding with IML are high-density polyethylene (HDPE) and polypropylene (PP). Both materials are durable and versatile, making them ideal for various packaging needs.

Typical Applications of In Mould Labels

In mould labels are commonly found in the following types of packaging:

- Personal care products like shampoo bottles, deodorant sticks, and soaps

- Food containers, including yogurt cups, ice cream tubs, butter tubs, and takeaway packaging

- Cosmetic packaging such as sunscreen and lotion tubes

- Household items like laundry detergent and cleaning supply containers

IML Plastic Containers

In mould labelling is widely used for creating thin-walled, disposable packaging, particularly for industries like food, personal care, household products, and cosmetics. The technique allows companies to add branding directly onto the packaging, eliminating the need for additional post-production labelling steps.

There primary method used to create plastic containers with in mould labels is injection moulding

In injection moulding, the pre-printed label is carefully placed inside the mould. After the plastic resin is heated, it is injected into the mould, where it combines with the label to form the final container.

Key Benefits of In Mould Labelling

Key Advantages of In-Mould Labelling (IML)

Superior Print Quality and Enhanced Visual Appeal

IML delivers high-definition print quality using offset printing techniques, producing vibrant, high-resolution images. A single label can cover the entire container, offering a 360-degree design that boosts product visibility on shelves. Labels can also be printed on both sides, allowing for creative 3D and curved designs, giving packaging a sleek, integrated appearance compared to traditional post-mould labelling.

Durability and Resistance

IML provides superior durability, with labels that are resistant to water, humidity, and extreme temperature conditions like freezing. The labels are scratch-proof, wrinkle-free, and highly resistant to impacts and abrasions, ensuring long-lasting, flawless packaging. Depending on the materials used, IML containers can also resist harsh chemicals, making them suitable for a variety of applications.

Environmentally Friendly

IML supports sustainability efforts by eliminating the need for external adhesives and simplifying the recycling process. Both the container and label are made from the same material, making the product fully recyclable. This eco-friendly process can reduce waste and allow for the creation of post-consumer recycled (PCR) products, helping businesses lower their carbon footprint.

Cost-Effective Production

IML combines the production and decoration of containers into one seamless step, reducing both production time and costs. This eliminates the need for blank container storage and secondary decoration processes. The efficiency of IML makes it an economical choice for large-scale production, while also delivering superior decoration quality compared to traditional post-production methods.

Versatile Design Options

IML offers brands flexibility in their packaging designs, allowing for the use of various materials, inks, and finishes. This versatility helps brands create customised packaging that stands out on store shelves and meets specific branding needs.

Quick Design Changeovers

IML automation allows for rapid design changes with minimal production downtime. This enables brands to switch between label designs quickly and efficiently, offering greater flexibility for updating packaging designs and responding to market trends.

Is In Mould Labelling Right for Your Business?

While in mould labelling offers numerous advantages, it may not always be the ideal choice depending on your specific needs. Consider these factors to determine if IML suits your business:

High Minimum Order Quantities: IML typically requires higher minimum order volumes due to the precision involved in creating and positioning the labels. This makes it an efficient choice for businesses that benefit from mass production.

Longer Lead Times: Because of the customized mould design needed for IML, lead times can be longer compared to traditional labelling methods. However, the long-term cost savings can outweigh the initial setup time.

Ensuring Success with In-Mould Labelling Projects

For an IML project to succeed, collaboration between all involved parties—such as label suppliers, moulding machine manufacturers, and automation experts—is crucial. Sharing production parameters and working together ensures a smooth and efficient process, delivering high-quality results every time.

By adopting IML, businesses can achieve premium packaging solutions that are cost-effective, sustainable, and visually compelling, making it a perfect fit for modern production needs.

Here at IML Solutions we cover every aspect of the process all under one roof!