Specialists in all aspects of In Mould Labelling!

- In - mould Labels

- Injection Moulding

- Integrated Manufacturing Solutions

Welcome to IML Solutions, your one-stop provider for all In-Mould Labelling (IML) needs. From product design and tooling to high-quality In-Mould Labels and full-scale production, we handle everything under one roof. Whether you’re looking for a single service or a complete IML solution, our expert team is here to assist you. With our comprehensive approach, we ensure seamless integration at every stage, helping you achieve exceptional results that stand out.

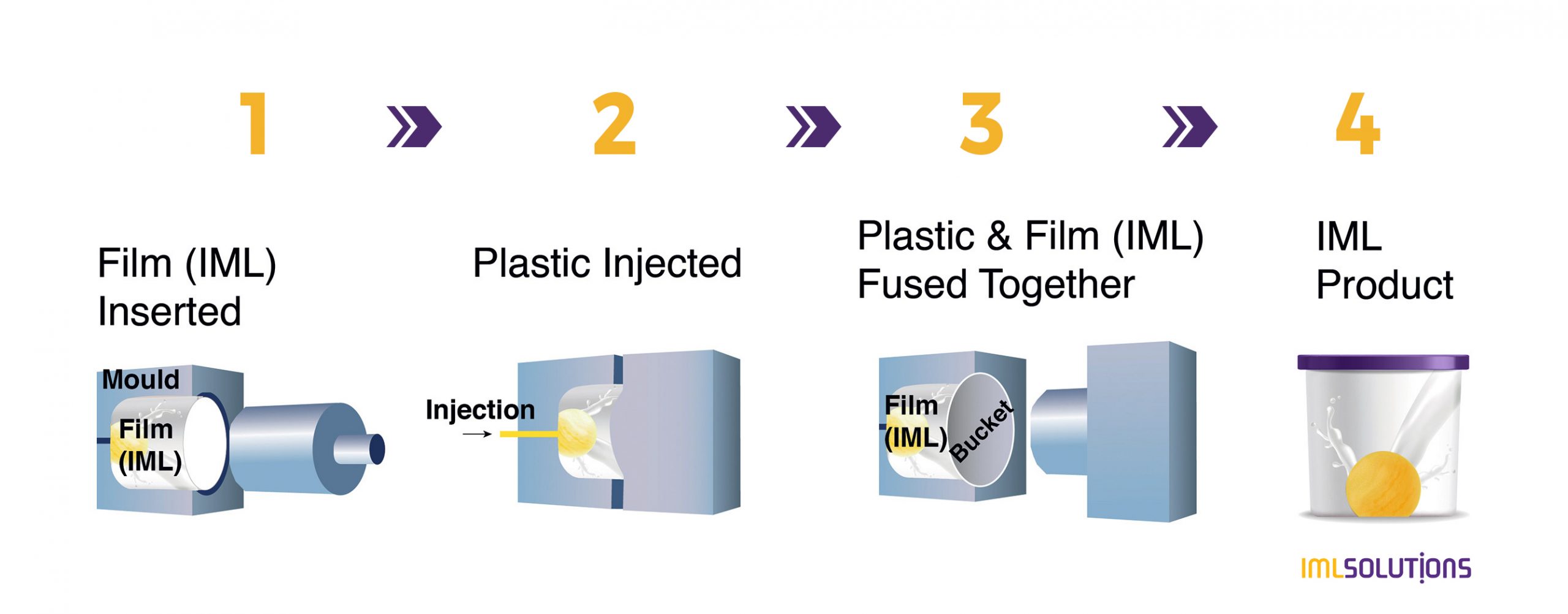

What is In-Mould Labelling (IML)?

In-mould labelling (IML) is an innovative technique increasingly used to decorate injection moulded products like plastic containers and consumer goods. In this process, a pre-printed label is placed inside the mould before the molten material is injected. The heat from the material bonds the label to the container, making it an integral part of the finished product.

Compared to traditional labelling methods like silk painting or pad printing, IML offers superior graphic quality, improved water resistance, and enhanced durability. By integrating the decoration directly into the moulding process, IML simplifies production and reduces overall costs.

This method is particularly favoured by industries such as food, healthcare, and chemicals. With the growing focus on sustainability, it’s important to understand that recycling plastic correctly can have a lower environmental impact than replacing it with materials that may increase carbon emissions, such as bamboo imported from distant locations.

What is required for a successful IML Project?

To successfully execute in-mould labelling (IML) within the injection moulding process, collaboration with the following key elements are essential:

Mould Maker

IML Automation

Provides the automation systems required to accurately place the labels inside the mould.

Injection Moulding Machine

Resin Supplier

Supplies the polypropylene (PP) or other plastic materials used in the moulding process.

IML Label Specialist

Markets

Beverage

Butter & Margarine

Confectionary

Dairy

Food

Home Care & Laundry

Ice cream

Paint & Outdoor

Beverage

Butter & Margarine

Confectionary

Dairy

Food

Home Care & Laundry

Ice cream

Paint & Outdoor

Looking for Custom IML Packaging Solutions?

We specialize in providing customizable In Mould Labels and In mould labelled products. Whether you require in-mould labels for an existing production line or you require a new product that is decorated with IML then we have the solution for you. Need further assistance? Our in-house team can help bring your vision to life. From initial concepts to final designs, we’ll ensure your product and label are perfectly aligned with your branding. Contact us today for a free consultation on our in mould labelling solutions!

Quick Contact

OUR LOCATION

Praesent ac sem eget est

PHONE NUMBER

01 23 45 67 89

EMAIL ADDRESS

info@sitename.com

Let's get in touch!

Have a question or need more information? Fill out the form below, and we’ll get back to you as soon as possible!