IML Production

Precision Injection and Moulding with IML

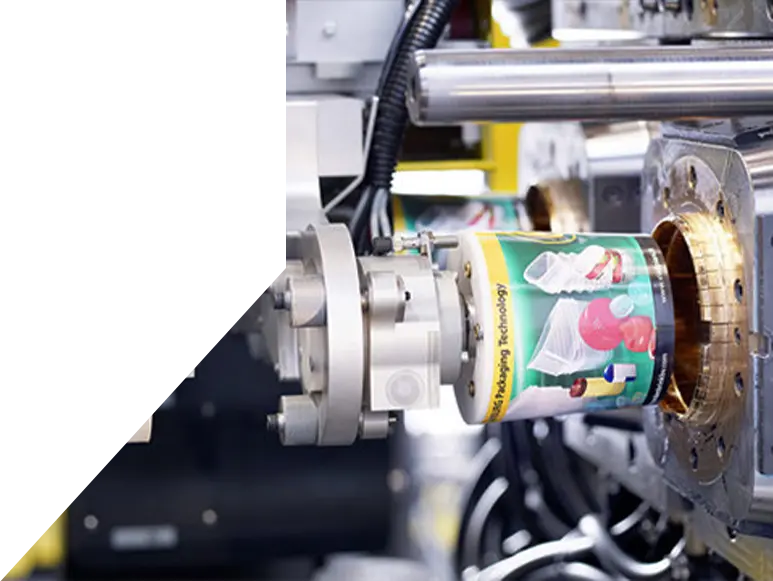

Injection moulding in the in-mould labelling (IML) process involves injecting molten material into a mould where a pre-printed label is already positioned. This technique is primarily used with thermoplastic and thermosetting polymers, making it ideal for producing high-quality, durable plastic products with integrated labels. The heat from the moulding process fuses the label and packaging, resulting in a seamless, finished product.

This method is widely utilised across industries for creating branded packaging that is both visually appealing and long-lasting.

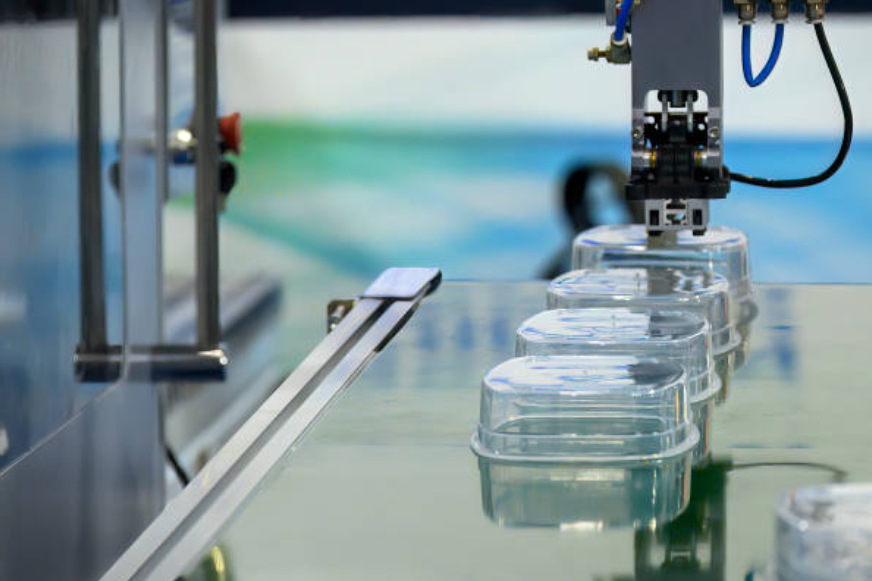

IML solutions core business is manufacturing In Mould Labelled parts.

- 10+ Moulding machines ranging from 100T to 350T meaning we can make IML products on single cavities all the way up to 6 cavities.

- Fully automated IML systems

- Operating 24 hours, 5 days.

- Real-time data systems for continuous monitoring and feedback.

Integrated Manufacturing Solutions

IML Solutions offers more than just injection moulding—we provide a full suite of services designed to streamline your production process:

- Reshoring and localisation support

- End-to-end product development projects

- Use of recycled-grade materials and sustainable packaging solutions

- Flexible stock holding agreements

- Efficient delivery with our fleet of vans and trusted third-party logistics

IML Solutions is committed to delivering tailored, efficient, and sustainable manufacturing solutions for your business needs.